ChatGPT & AI in

Procurement Course

Free Preview Lesson

Written by Marijn Overvest | Reviewed by Sjoerd Goedhart | Fact Checked by Ruud Emonds | Our editorial policy

Supply Chain Forecasting — Everything You Should Know

Key takeaways

- Supply chain forecasting refers to predicting demand based on past and present information to help in decision-making.

- Changing regulations, such as those related to international trade, can disrupt supply chains.

- Product returns complicate supply chain forecasting by altering customer shopping patterns.

Supply chain forecasting enables accurate predictions from past and present information making it critical to an organization’s success. However, how do you forecast effectively?

In this article, you will learn what supply chain forecasting is. We will tell you the importance and the methods used in supply chain forecasting. Additionally, we will show you the challenges the supply chain faces today making it difficult to forecast.

Once you are done reading this article, you will know how to forecast supply chains that can promote growth in your company. Additionally, you will be better equipped on what methods you can use in a specific situation in your supply chain.

I created a free, downloadable Excel template for procurement professionals. This spreadsheet helps you track and analyze procurement metrics, which are essential for forecasting and effective supply chain management. I also included a video tutorial, together with a PowerPoint presentation, explaining how to use the template.

What is Supply Chain Forecasting?

Supply chain forecasting refers to the process of predicting demand by looking at past and present information to help businesses make decisions about their plan, budget, and stock inventory.

All data and information in forecasting ensure that businesses will run smoothly and continuously grow. Although it always relates to demand and sales projections, forecasting can also be used to determine product pricing, lead times, labor needs, and more.

Integrating AI into forecasting improves accuracy, saves money, and helps businesses react to exceptions real time. Additionally, it can provide more effective insights to ensure a flexible and agile supply chain.

The Importance of Forecasting in Supply Chain

Timing is very important, especially for forecasting as it ensures that you have the right amount of product in stock. Having too little in stock means running out at unfortunate times when the demand is high, causing your buyers to buy elsewhere. However, having too much means paying unnecessary high costs for your inventory.

Demand forecasting can analyze how many products your customers may likely order during a specific week, month, or quarter. Thus, it allows organizations to keep a suitable volume in the inventory which is enough to fill customer orders.

Effective price forecasting can also help businesses to predict when the price of products increases or decreases may affect customer demand. Forecasting enables companies to have better insights to make robust strategic planning that will ensure that suppliers can meet your demand.

Furthermore, by being able to predict customer demand, you can control your supply chain to fulfill customer orders on time and lessen the risk of running low on stock. Thus, establishing a sense of trust between your customers and your company.

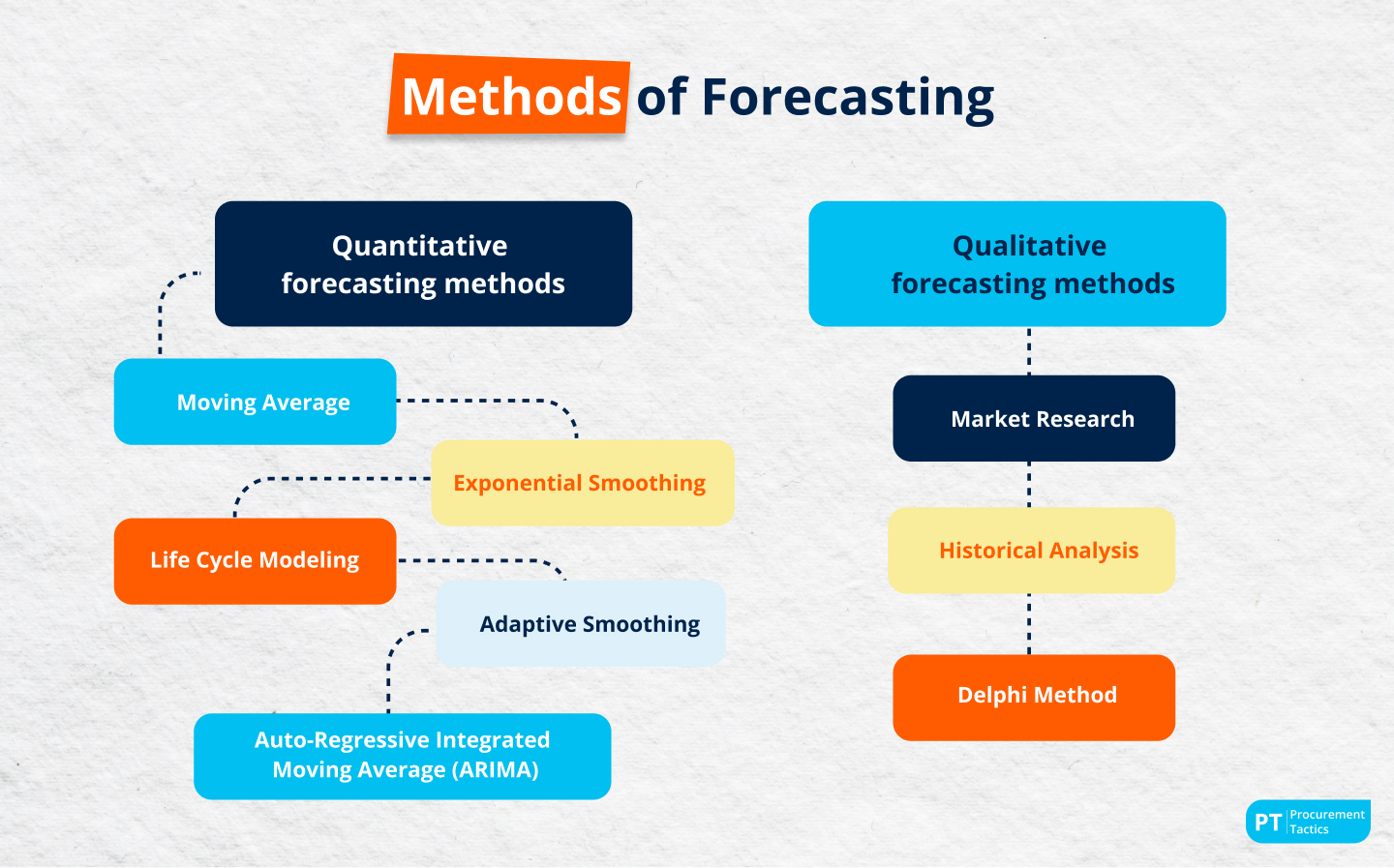

Methods of Forecasting

In forecasting supply chain, there are two predominant methods which are the quantitative and qualitative forecasting methods.

1. Quantitative forecasting methods

The quantitative forecasting method uses historical data to predict future sales. Using data-driven insights gives companies an analytical approach to making better decisions on how to plan for the future.

Here are the most common approaches when it comes to the quantitative method:

- Moving Average

The moving average is one of the simpler methods in quantitative forecasting which is based on historical averages. The average is used to make a prediction of the upcoming period and frequent recalculation is done every month, quarter, or year.

However, the moving average treats all data equally and does not take into account that recent data may be a better indicator of the future and should be given more importance.

Additionally, it does not allow for trends. Thus, this approach is only best for inventory control for low order volume.

- Exponential Smoothing

This approach uses weighted averages with the assumption that past trends will mirror the future. This method takes into account past information but gives more focus to recent observations.

If you use the right tools, the exponential smoothing approach can be easy to use and is ideal for short-term forecasting.

- Adaptive Smoothing

The adaptive smoothing approach utilizes multiple variables to make a prediction. It provides a close look into changes from period to period and determines specific patterns or trends.

This approach enables businesses to focus on specific variables to make better decisions. However, it requires automation tools that collect, record, and aggregate data in real-time.

By using automation, businesses can use this approach by making accurate predictions across a large product catalog.

- Life Cycle Modeling

This approach analyzes the growth and development of a new product. It needs data across different market segmentation such as creators, adopters, and early and late majority.

In life cycle modeling, it determines the future performance and demand of a specific product across various markets. This helps brands to know how long the product will be in demand, and distribute and market new products

- Auto-Regressive Integrated Moving Average (ARIMA)

Auto-Regressive Integrated Average or ARIMA is one of the most accurate forecasting methods and is best suited for forecasting up to 18 months or less. However, this approach is very time-consuming and costly.

2. Qualitative forecasting methods

Many e-commerce brands use a combination of both quantitative and qualitative methods to get as accurate predictions as possible. However, qualitative methods are much more helpful when there is a lack of data.

Usually, new businesses rely on qualitative forecasting methods to make predictions. Here are some common approaches under this method:

- Market Research

Market research is the most common type of qualitative forecasting method which is considered as the best practice for any business, whether you are selling a product or service.

It often uses polling, surveying, or interviewing a specific target demographic. It can be executed internally by marketing or sales experts or by hiring a third party that specializes in market research.

Market research can be used to predict supply and demand, and help identify whether or not there is a strong demand for products that will support the profit goals of your company.

- Historical Analysis

Historical analysis is an approach that uses the sales history of a product that has a parallel relationship with a present product to predict future sales.

The data for historical analysis can also be collected by looking at your competitor’s high-selling products and comparing similar products of your company to know when demand is possible.

While this approach can work in the long term, it is not advisable to be used for the short term.

- Delphi Method

Delphi’s method consists of market orientation and opinions within a small group of experts which is then grouped and analyzed by third-party experts.

The opinions of each expert are collected individually to avoid the influence of other experts’ opinions, which are different from a panel discussion or focus group.

Once all the information is reviewed, it will be summarized with an emphasis on different patterns before handing the results over to the company to review. This method has been proven to be effective and dependable for long-term forecasting.

Challenges That Forecasting in Supply Chain Faces Today

The following are some of the challenges in forecasting that supply chain faces today:

1. Changing regulations

Changes in regulations between countries can greatly disrupt forecasting as supply chains adapt to comply with new laws and past data becomes less relevant.

Just like what happened at the start of COVID-19, emergency laws were passed around the world to close borders and stop travel which ultimately slowed down trade.

The impact is still ongoing as there is still congestion in many ports all around the world. Combined with the ongoing war between Ukraine and Russia, it’s easy to determine how these factors can disrupt supply chains and supply chain forecasting.

2. Changing trends

Although changing trends are constant in this world, the unpredictability with which they change remains a threat to forecasting. For example, the pandemic has forced consumers to go online to purchase their needs. Thus, many businesses tried to adapt quickly to meet the demands of their customers.

3. Product returns

Product returns are considered a cost of doing business nowadays, However, they also changed how customers shop. Many online shoppers order multiple products, find the right fit, and return the rest. Thus, these returns can complicate supply forecasting.

4. Seasonality of products and supplier lead times

Not taking into consideration the seasonal and peak periods in the supply chain will easily disrupt your forecasting.

These periods in the calendar usually impact ocean freight and should be planned in advance. If not, you will miss out on opportunities to capitalize on the increased demand.

You must take into consideration that different suppliers and manufacturers will have different lead times, not just solely based on the services they provide, but they also have their own seasonal or holiday calendars. This is the reason why a strong relationship with your suppliers is important.

I don’t think it’s necessary to explain how important accurate forecasting is. A forecast that is too high puts a strain on your working capital, while a forecast that is too low leads to potential missed sales.

In my experience as a procurement manager at various large companies, where I closely collaborated with the supply chain department, I’ve seen many different methods of forecasting. I don’t believe there is one perfect way to do it, as it depends on various factors as mentioned above.

The biggest dependency lay in the number of items a company sells and the extent of promotions and seasonality. For the procurement of our olive oil, which was rarely on promotion, you could almost manually calculate the expected sales based on past results.

I’ve also worked at a company where millions of products were sold, all with different promotion pressures and sales patterns. In this case, it’s much more important to set up the data in a scalable way where a correct forecast is generated based on expected purchases

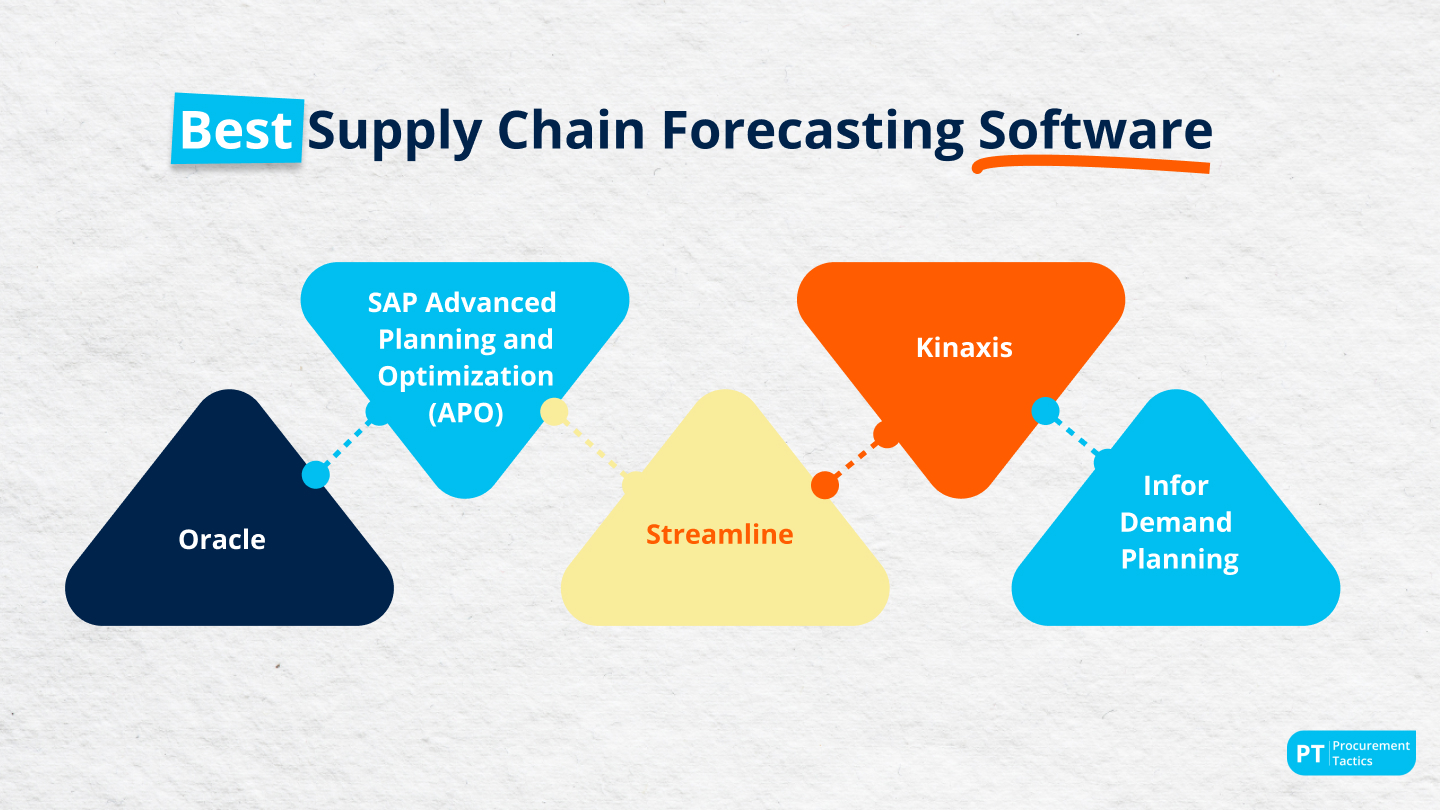

Best Supply Chain Forecasting Software

Forecasting is hard, especially if you do not know where to start. Thus, here are some of the best tools that can help you in forecasting your supply chain efficiently.

1. Oracle

Oracle Supply Chain Planning Cloud combines forecasting algorithms with flexible analytics to help you adopt a customer-centric demand strategy.

This cloud-based system is suited for industries such as automotive, industrial manufacturing, retail, wholesale, and distribution as it helps its clients to handle operations in real-time and plan for better customer service.

Moreover, it has a key feature that visualizes and tracks forecast factors such as baselines, trends, and seasonality while maintaining causal correlations and adjusting for built-in exceptions.

2. SAP Advanced Planning and Optimization (APO)

SAP APO is a cloud-based software tool that helps its users to plan, execute, optimize, and track their logistic processes on the operational and strategic levels.

This specific module of SAP offers planning layouts, planning books, and a demand planning library of statistical forecasting and macro techniques.

By utilizing these, you can adopt a consensus-based approach to make demand plans and forecasts with inputs from different departments of your organization.

3. Streamline

Streamline is a supply chain forecasting software that has hundreds of partners across the world and thousands of enterprise customers.

It has an integrated proprietary AI in its system which can tell you when and what techniques to apply to effectively forecast demand.

4. Kinaxis

Kinaxis is a cloud-based application that can help you create a collaborative and comprehensive demand forecast based on statistical and functional perspectives.

Additionally, it provides visibility of your supply chain with the ability to integrate demand functions with other supply chain processes. Thus, it greatly improves the accuracy of the forecast and efficiently executes plans across departments in your company.

5. Infor Demand Planning

Infor is a fast and highly collaborative cloud-based system that can help you create new plans and manage existing plans. It can also help you optimize your operation to meet demand, reduce costs, improve services, and increase the efficiency of your operations.

Infor has a feature that detects variances in demand patterns for every inventory item. Additionally, it applies a framework that can deliver accurate forecasts using probability and historical trend analysis.

Procurement Expert’s Advice on Supply Chain Forecasting

For this article, we asked an experienced procurement expert to share her insights to help answer common questions about forecasting in the supply chain.

Faiza Iftikhar

Co-Founder, Procura

Pakistan

LinkedIn Profile: linkedin.com/in/faiza-iftikhar

1. Can you give us an example of supply chain forecasting and how to forecast effectively?

- Gather historical sales data.

- Analyze market conditions and seasonality.

- Use statistical models and technology.

- Collaborate with stakeholders.

- Continuously adjust based on real-time data.

- Maintain safety stock.

- Communicate forecasts to the supply chain.

- Establish a feedback loop for continuous improvement.

Here’s an example: Retail Clothing Store Supply Chain Forecasting

Scenario: A clothing retailer is preparing for the change of seasons and wants to forecast demand for a specific line of winter coats.

Steps for Effective Forecasting:

1. Data Collection: Gather historical sales data for the winter coats from previous seasons, including variations in demand based on weather conditions.

2. Market Analysis: Consider external factors like weather forecasts, economic conditions, and fashion trends that can impact coat sales.

3. Statistical Models: Utilize time series analysis to identify trends and patterns in coat sales data over time.

4. Collaboration: Collaborate with the store managers and regional sales teams to gather on-ground insights and validate assumptions.

5. Adjustment: Continuously monitor weather forecasts and actual sales data to adjust inventory levels as needed.

6. Safety Stock: Maintain safety stock in case of unexpected weather fluctuations or surges in demand.

7. Communication: Share the forecast with suppliers and distribution centers to ensure timely restocking.

8. Feedback Loop: After the season, analyze the accuracy of the forecast and incorporate lessons learned into future forecasting models.

By following these steps, the clothing retailer can effectively forecast demand for winter coats, optimize inventory management, and ensure they have the right products in stock to meet customer needs as the season changes.

2. What tips can you give to procurement professionals about supply chain forecasting?

1. Prioritize data quality.

2. Use diverse forecasting methods.

3. Collaborate with other departments.

4. Consider seasonality and trends.

5. Continuously monitor and adjust.

6. Include safety stock.

7. Conduct scenario analysis.

8. Implement automation tools.

9. Establish a feedback loop.

10. Educate your team.

11. Stay informed about industry trends.

12. Be mindful of ethical considerations in data usage.

3. What is the most important lesson you learned in forecasting the supply chain?

The significance of adaptability and continuous improvement.

Supply chain conditions can change rapidly, and successful forecasting requires the ability to adjust strategies, models, and methods as needed to accommodate shifts in demand, supply, and external factors.

Staying flexible and being open to refining forecasting processes is crucial for long-term success in supply chain management.

Conclusion

Accurately forecasting supply chain demand is a critical component of achieving organizational success. It informs decisions on budgeting, planning, and inventory management.

This process involves analyzing past and present data to predict future demand. In today’s constantly evolving business environment, AI integration into forecasting processes can enhance accuracy, reduce costs, and allow for real-time adaptability.

Moreover, ensuring the right balance of stock is crucial in forecasting, and accurate predictions play a vital role in achieving it. It helps prevent both stockouts and excessive inventory costs.

Forecasting also has a significant impact on strategic planning, pricing decisions, and building trust between businesses and their customers.

Frequentlyasked questions

What is supply chain forecasting?

It refers to the process of looking at past and present information to help businesses predict demands.

Why is it important?

It allows businesses to ensure that they have the right amount of product in stock to prevent dead stock in their inventory and to improve customer service.

How can you forecast supply and demand?

You can forecast supply and demand by using quantitative and qualitative methods. However, quantitative methods tend to be more accurate as they are based on hard data and analysis.

About the author

My name is Marijn Overvest, I’m the founder of Procurement Tactics. I have a deep passion for procurement, and I’ve upskilled over 200 procurement teams from all over the world. When I’m not working, I love running and cycling.