ChatGPT & AI in

Procurement Course

Free Preview Lesson

Written by Marijn Overvest | Reviewed by Sjoerd Goedhart | Fact Checked by Ruud Emonds | Our editorial policy

Supplier Management – The Ultimate Guide of 2024

Key take-aways

-

Strong supplier relationships are vital for meeting the organization’s demands and success.

-

Qualify, segment, collaborate, and evaluate to optimize supplier performance.

-

Cost savings, transparency, and risk mitigation through supplier management and collaboration.

Supplier management is crucial for organizations that have many vendors or suppliers. They need to manage their supplier to maintain the relationship that they have built. However, this is not an easy task for organizations.

For this article, we will discuss what supplier management is. We will tackle how important it is for organizations to manage their suppliers well. Additionally, we will show you the supplier management process and how it benefits you. We will give you tips on improving supplier management in your organization.

Once you are finished reading this article, you will be able to employ all the learnings that you have in your organization. Additionally, you will know how to improve your current supplier management which will help the organization grow to its potential.

What is Supplier Management?

Supplier management refers to the process of handling and improving interactions with the suppliers or vendors of the organization. It includes evaluating the strengths and capabilities of the supplier.

Supplier management is the relationship that has been created between an organization and its preferred supplier. It is a process to manage suppliers and improve their impact on the development of the organization.

Why is it Important?

The organization relies on the goods and services the vendors or suppliers provide. It is obvious why a strong relationship with your supplier is important. However, many organizations create problems for themselves due to a lack of supplier relationship management and strategic sourcing.

You must take note that the success of the organization is also dependent on the supplier’s ability to meet the demands and deliver the goods on time.

Supplier management allows the organization to know potential performance issues, implement open communication, and ensure that the suppliers support the organization by complying with the requirements.

What are the Steps Involved in the Supplier Management Process Flow?

Here are the steps to guide you in the Supplier Management Process Flow.

1. Qualification

This is the first step of the supplier management process. Of course, the organization needs to evaluate suppliers to determine if they can provide and meet the demands set by the organization.

2. Segmentation

Segmentation is the classification of suppliers into specific supplier quadrants based on preset metrics such as supply criticality, supply risk, profitability, performance, and more.

3. Collaboration

Collaboration is the process that paves the way for the organization and the supplier to create a strong relationship. Additionally, it improves the commercial value through process and performance advances and product or service innovation.

4. Evaluation

Evaluation of the supplier is the last step of the supplier management process flow. It measures the supplier’s performance and ensures that they meet the terms they agreed on in the contract.

Additionally, evaluation is performed based on several metrics like price, production, quality, delivery time, and services.

It is also important to evaluate the suppliers based on their ability to handle unexpected procurement crises or emergencies like the COVID-19 pandemic.

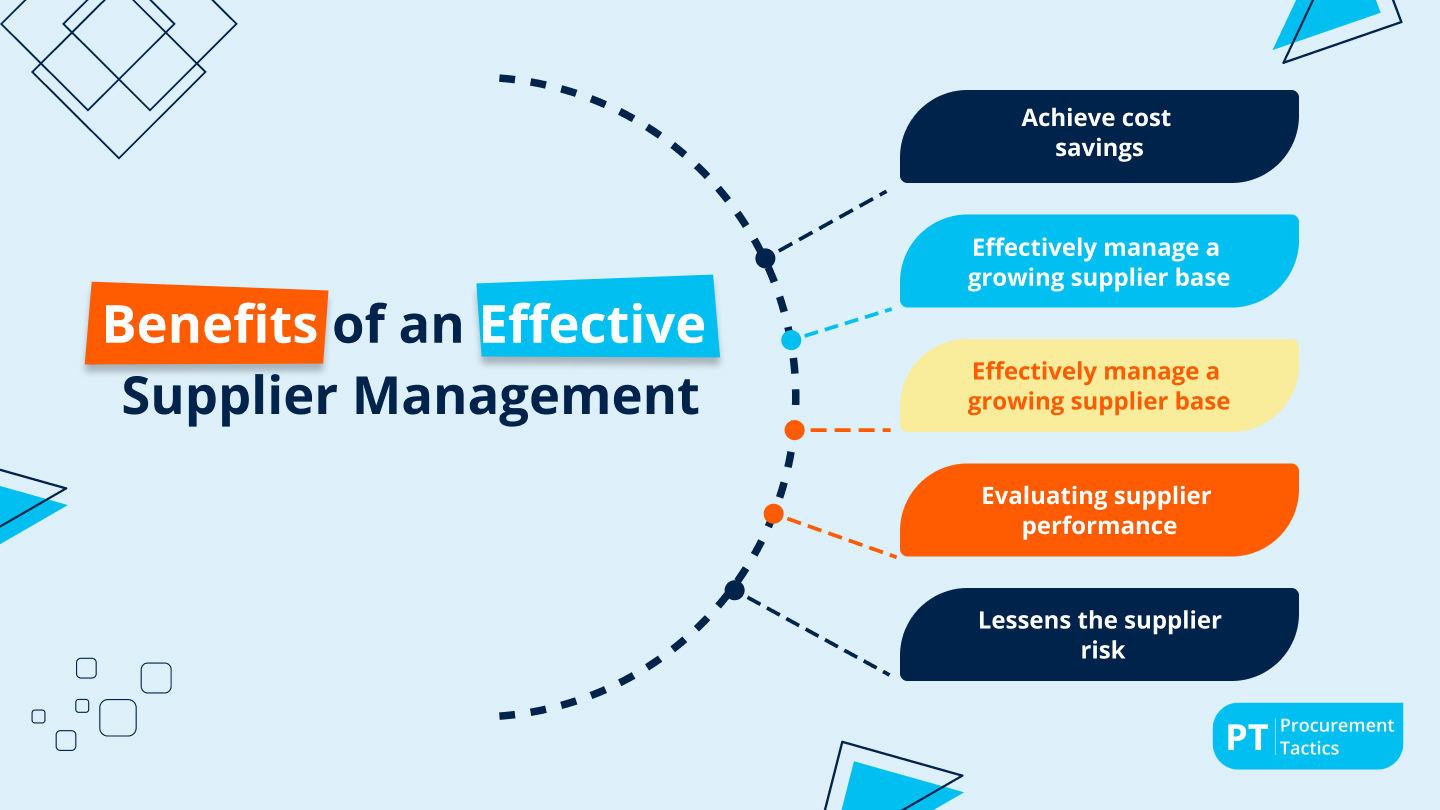

The Benefits of an Effective Supplier Management

There are various benefits in having an effective Supplier Management and listed below are some of them.

1. Achieve cost savings

Strong supplier management will enable the organization to find cost-saving opportunities in the supply chain. It drives a new level of efficiency and productivity by enabling smooth supplier connectivity and collaboration.

2. Effectively manage a growing supplier base

It is not a surprise that most organizations have many suppliers and they need to deal with them simultaneously. A well-structured supplier management process will allow the organization to manage its multiple suppliers all at once.

3. Improves transparency

A supplier management system will allow the organization to streamline information and data regarding the life cycle of the suppliers.

Additionally, it enables organizations to have transparency with the number and type of suppliers they engage with.

4. Evaluating supplier performance

The organization needs to know how its suppliers are performing because its performance is dependent on them. Supplier management will allow the organization to evaluate the supplier’s compliance and give insights into their performance.

5. Lessens the supplier risk

Efficient supplier management can help find and evaluate the impact of supplier risks and create appropriate risk mitigation measures.

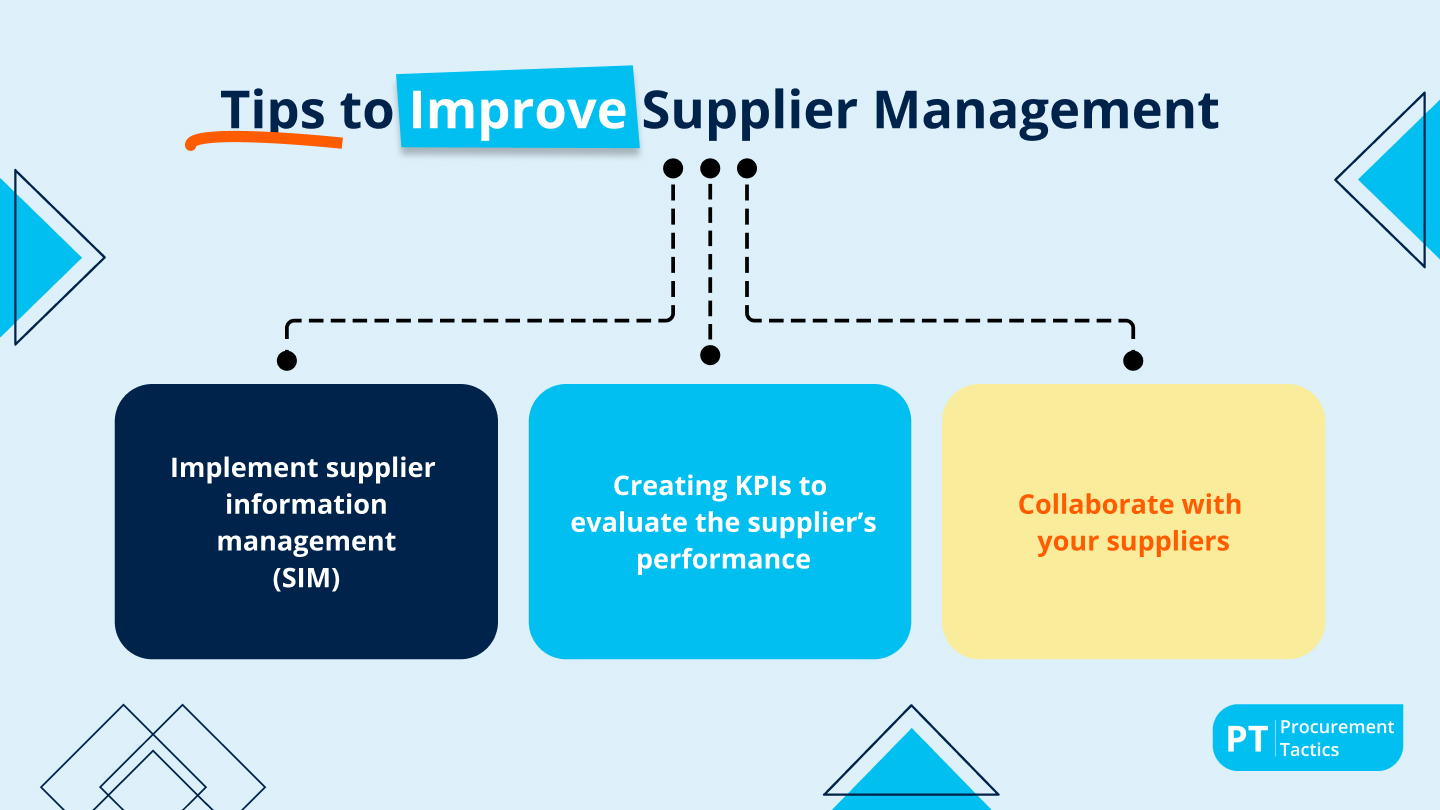

3 Tips to Improve Supplier Management

These 3 tips are significant in your Supplier Management journey so make sure to pay them close attention.

1. Implement supplier information management (SIM)

Implementing supplier information management will enable you to:

- Streamline supplier data that can give you meaningful insights into their performance

- Monitor the supplier’s capabilities

- Evaluate supply risks and create measures to mitigate it

2. Creating KPIs to evaluate the supplier’s performance

Key performance indicators (KPI) enable supplier performance measurement to assess the value-creation and find the problem in the process.

3. Collaborate with your suppliers

The organization must ensure that it has communicated its objectives and goals coherently to its suppliers.

When the suppliers understand what you want, they can offer propositions that can provide value for your needs.

Supplier relationship management can be the key to deriving maximum value from the suppliers to make the supply chain of the organization work efficiently.

Procurement Expert’s Advice on Supplier Management

For this article, we asked a seasoned procurement professional to share his insights regarding supplier management.

Sjoerd Goedhart

Owner, Goedhart Interim Management & Consultancy

LinkedIn Profile: https://www.linkedin.com/in/sjoerdgoedhart/

1. Can you share a personal example of supplier management? What can readers learn from this?

“During the recent Ukraine crisis, a lot of companies became out-of-stock in some essential raw materials. Existing suppliers could only continue delivery if increased prices are paid. Especially in the example of out-of-stock raw materials, it is essential to have alternative suppliers approved and available to deliver to minimize the effect of nonavailability of raw materials.”

Follow-up Question: Your example shows the importance of having alternative or multiple suppliers. However, what if there is only one supplier that supplies your needed materials (sole sourcing)? What is your advice for procurement professionals who are facing this kind of situation?

“In a situation where there’s only one supplier for the needed materials, it’s crucial for procurement professionals to establish clear expectations, KPIs, and conditions that the supplier must meet. This includes outlining service levels and adhering to quality regulations. Additionally, implementing short-term contracts allows for regular evaluations and provides an opportunity to renegotiate terms if necessary. By maintaining proactive communication and leveraging contract flexibility, procurement professionals can effectively manage the situation despite having only one supplier.”

2. What should readers know about this supplier management?

“Good supplier management always saves money because suppliers know that alternative suppliers have been approved and are ready to deliver. In addition, good supplier management also provides alternatives if incidents occur in the supply chain to ensure that the manufacturer experiences little or no inconvenience from a disrupted supply chain. If you, as a manufacturer or retailer, have this done well, it gives you an advantage over your competitors.”

Follow-up Question: What obstacles have you faced when implementing or maintaining effective supplier management? How did you overcome them?

“One common obstacle in implementing or maintaining effective supplier management is workload constraints within the organization. Often, there isn’t enough time to dedicate to supplier management qualitatively, leading to shortcuts or compromised efforts. To address this, it’s essential to communicate the workload challenges to management and advocate for additional resources or support. However, in some cases, adding extra manpower may not be feasible. In such instances, it’s crucial to establish clear priorities and align them with management expectations. Setting priorities ensures that efforts are focused on the most critical tasks. Additionally, regular communication with management helps to ensure alignment and avoid potential conflicts over task completion. Ultimately, successful supplier management requires navigating internal politics and ensuring that agreed-upon priorities are delivered upon effectively.”

3. What is the biggest misconception about supplier management? What do most people get wrong about it?

“Supplier management, and especially the selection and alignment of alternative suppliers, costs time and money, which can also be used to strengthen the relationship with existing suppliers. Good supplier management is essential to ensure the supply of goods and have the best prices.”

4. How can businesses effectively assess and manage supplier performance to ensure quality and reliability?

“To set clear KPIs for what suppliers should deliver. Share the KPIs with the suppliers and track and evaluate them several times during the year.”

5. Can you give some tips on how one can manage their suppliers well?

“Having a supplier management system that is used by all procurement professionals. Important to do e.g. target setting for the professionals to ensure that supplier management is a structural part of the daily activities and that the supplier management system is actively maintained.”

6. How can software or tools help procurement professionals determine the supplier that suits them the most?

“It helps to have good software tools available to keep all supplier data up to date and insights, as well as the performances of existing suppliers. Together with tools to compare and benchmark cost prices, this makes it possible to efficiently manage suppliers’ performance and select suppliers that best suit the manufacturer’s objectives, both in terms of quality and/or price.”

Conclusion

In essence, the significance of supplier management cannot be overstated in procurement. It is the linchpin that sustains operational efficiency, ensures resource availability, and fosters collaborative, mutually beneficial partnerships.

An adept supplier management system is the cornerstone of success in optimizing the overall value chain.

As organizations navigate the complexities of the business landscape, the judicious cultivation and management of supplier relationships emerge as a strategic imperative, empowering procurement professionals to secure sustained success in an ever-evolving marketplace.

Frequentlyasked questions

What is Supplier Management

Supplier management refers to the process of handling and improving interactions with the suppliers or vendors of the organization.

Why is Supplier Management important?

It is important to assess the performance of your suppliers as the performance of the organization is dependent on theirs.

What are the benefits you can gain from Supplier Management?

Implementing supplier management will allow the organization to achieve cost savings, manage many suppliers, improve transparency, and evaluate the supplier’s performance.

About the author

My name is Marijn Overvest, I’m the founder of Procurement Tactics. I have a deep passion for procurement, and I’ve upskilled over 200 procurement teams from all over the world. When I’m not working, I love running and cycling.