Procurement spend data is often unstructured, difficult to interpret and unreliable as a source of truth. Poor data quality is one of the biggest challenges that procurement leaders face when embarking on a digital transformation agenda or procurement excellence journey. Addressing this beforehand – or at least having an awareness of it – is the best plan of action.

We will examine some of the reasons why procurement spend data is so messy. Then, we’ll go on to look at some ways of potentially fixing this before embarking on a transformation.

One thing is clear: putting garbage data into a modern digital procurement tool is going to be a bit like trying to drive a Ferrari down a gravel track. It’s not the Ferrari or the driver’s fault that it’s not able to deliver peak performance.

The same applies when we face the challenge of dirty procurement data.

Procurement’s dirty spend data: why, and what to do?

So, how did we arrive at this problem?

My take on this is that it’s a mixture of two things.

Firstly, Procurement often finds itself reporting into functions or leaders who don’t have the same incentive and urgency for procurement data accuracy that we do.

Additionally, if we don’t have the much-maligned “seat at the table”, then we must at least have have sponsors and advocates in the boardroom. If we don’t, then it’s difficult to make the case from the bottom up for an investment into clean procurement data.

Secondly, procurement data often comes from fragmented sources, and many more people have touch points into it within an organisation than is the case with customer data, for example. There’s also the lack of overall ownership of the problem.

And then finally, the never-ending challenge of taming and controlling the long tail of non-strategic, non-complex spend which often isn’t directly managed by Procurement.

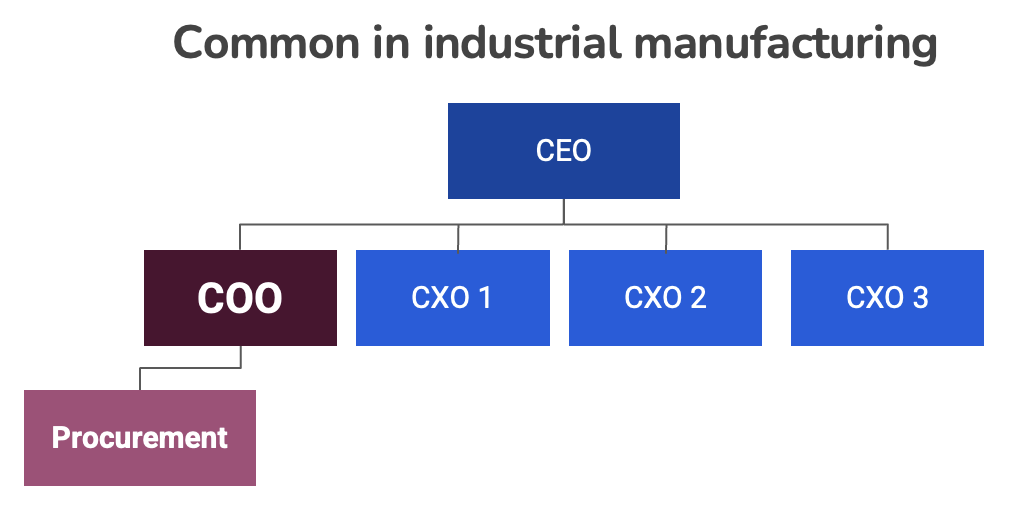

Where does Procurement typically report into?

To understand why Procurement spend data is often so poorly structured, let’s first take a look at where the function typically reports into.

Industrial Manufacturing

In manufacturing businesses, it’s pretty normal that Procurement reports into Operations. It stands to reason that if 60-70% of revenue in these businesses is spent on goods and services from external suppliers, then Procurement and Operations are going to be heavily dependent on each other to succeed.

Does Operations fundamentally care about purchasing data though? As long as lead times, bills of material and material specifications are maintained for direct materials, then the remainder is likely not a priority.

Also, we haven’t considered indirect procurement spend. It’s no coincidence that indirect spend is usually an afterthought, and consequently often a mess, in manufacturing businesses.

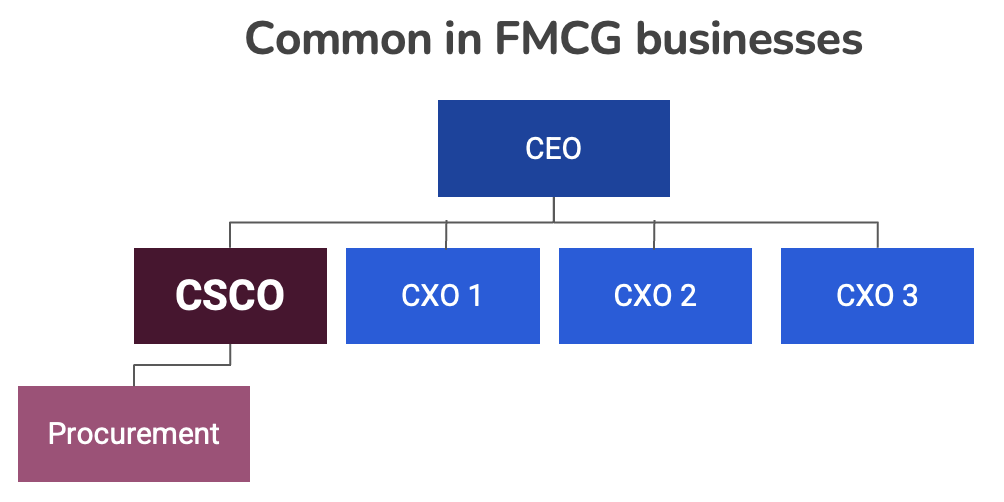

Fast Moving Consumer Goods

FMCG businesses (or CPG to our American readers) are built on slick supply chains which foster brand value and delight customers. That’s why Procurement often sits within the Supply Chain function.

For similar reasons to industrial manufacturing businesses, Chief Supply Chain Officers often don’t place much importance on indirect spend. And, while marketing and IT may have more prominence here, due to their critical nature to these businesses, the remainder of the indirect spend is often unstructured and decentralised.

Not to mention that many of these companies have grown by acquisition and are multinational by nature. The result is multiple ERP systems and data warehouses being present across different regions or Business Units. All too often, these systems don’t effectively integrate with each other.

Service industries and tech companies

In non-manufacturing businesses, Procurement will typically report into the CFO.

Finance usually understands the importance of clean data for a smooth P2P process and fraud prevention. However, it can often be a challenge to make a compelling business case beyond this.

We know that a foundational data cleaning and maintenance exercise across all vendor master and spend data will drive savings opportunities. However, it’s difficult to come up with a hard number to justify the business case.

The result?

Usually, we don’t get the investment, and procurement data remains disjointed and unreliable.

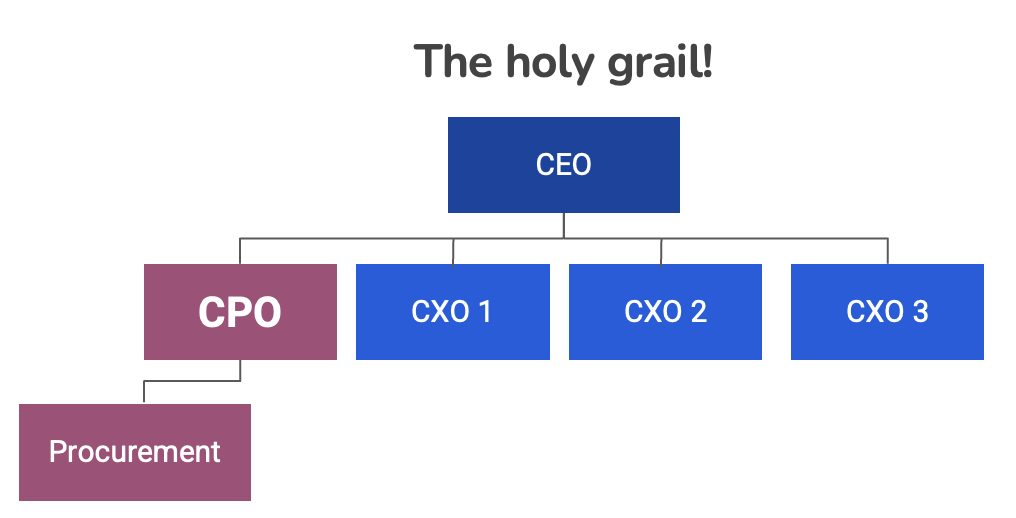

Where would we like to be?

Of course, the ideal situation would be a CPO who reports directly into the CEO. This person can then influence and persuade the C-Suite directly.

By making the case for clean procurement spend data to be a strategic driver of competitive advantage to the business, investment can be secured without having to go through a CXO from another part of the business as the gatekeeper.

If Procurement has a seat on the Board, there is a greater incentive and higher likelihood of securing a budget to fix this problem.

Which leads us on to the next challenge – a lack of overall ownership….

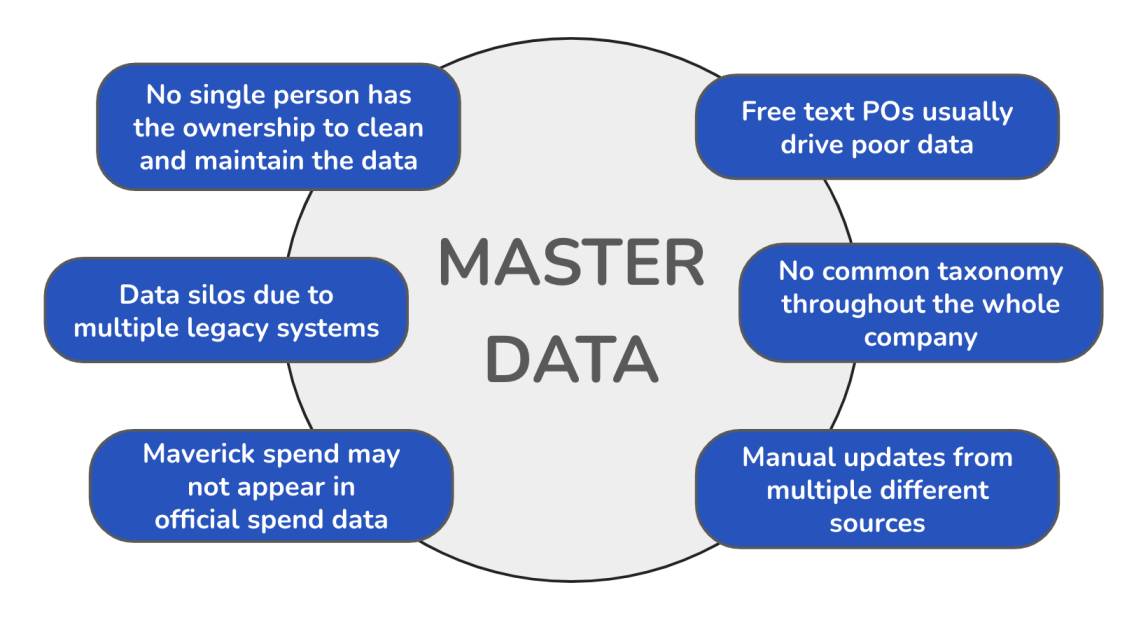

Why is there no clear ownership of spend and vendor data?

There are so many different touch points of where data quality can be impacted.

Let’s take a look at some of these in the graphic below.

Without an overall owner and governance process covering the entire area of master data, it becomes virtually impossible to stay on top of data quality.

Starting off clockwise, if free text orders can go through the system, PO line item data is compromised. A lack of common taxonomy throughout the organisation can mean that different spend from the same supplier is categorised into different buckets. Updates can come from different sources e.g. Accounts Payable, Stores, Logistics, and suppliers themselves.

If maverick spend is not booked into the system through a PO and invoices are just paid based on email approval, then this spend often doesn’t show up. Then we’ve got the challenge of legacy ERP systems that don’t speak to one another.

Bring all of this together with the final hammer blow of nobody having overall ownership of the problem, and it just festers and gets gradually worse.

However, there’s still one place where the majority of the problems usually originate…

Dirty data usually comes from Tail Spend and Free Text POs

So, we’ve examined why having clean procurement data is often not a priority.

Let’s now look at the biggest culprit of where spend data is usually messy and not maintained.

A long tail of non-strategic spend, with suppliers not actively managed by procurement, is a fertile breeding ground for dirty data.

These POs are often raised using free text, and usually don’t have much (or any) involvement from Procurement. If Operational Purchasing teams are not aware of the importance of clean data, material / service group taxonomy, and checking for duplicates, this is where the quality of the data usually goes awry.

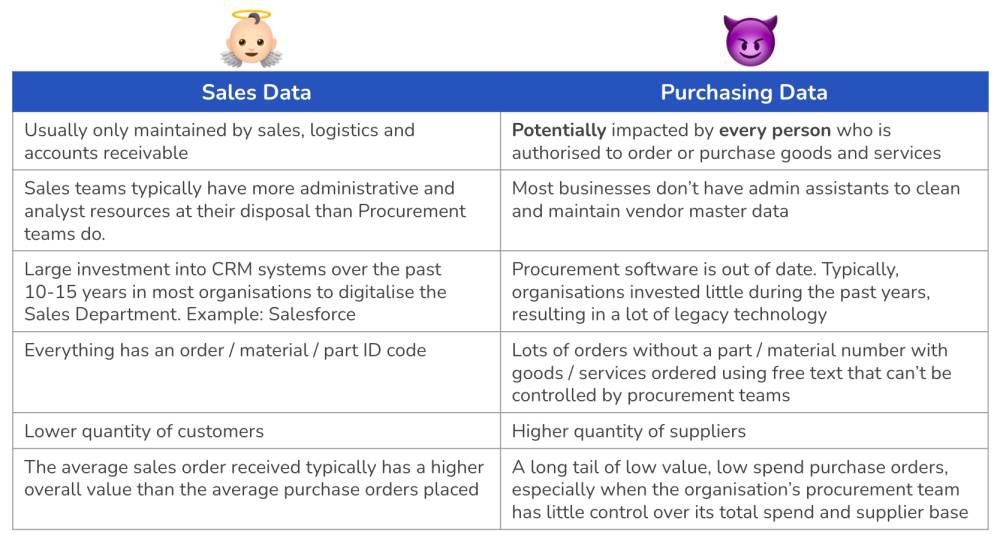

Let’s compare this to sales data for goods and services sold to customers. This typically doesn’t have these same challenges.

If sales data is clean, why is purchasing data messy?

It’s a perfectly logical question to ask. You would think that maintaining one should not be any harder than the other.

If we dig a big deeper though, we quickly find that this isn’t the case.

Relatively few people within an organisation touch sales and customer data. Unless you work in a Direct-to-Consumer (D2C) e-commerce business, you’re almost certainly going to have more suppliers than customers.

And that’s before taking into account how much investment into technology Sales teams have received vs. Procurement. Add to this the headcount and administrative support that Sales departments typically have at their disposal when compared to Procurement.

So, how can digital procurement tools fix the problem?

Let’s start by saying there is no magic bullet.

Spend analytics platforms are definitely now getting much better at categorising spend. Using AI and Machine Learning, some of the best-in-class applications are now able to hit over 90% accuracy. You still need to provide the taxonomy and check the data classification though!

Intake, Supplier Relationship Management (SRM), vendor master data portals, e-procurement and autonomous sourcing tools are all ways that certain aspects of the dirty data problem can be tackled.

Understanding the underlying root causes of what is driving your biggest spend data management issues is an essential starting point on this journey. Once you’ve got your head around this part, figuring out what type of tech can help you to fix the challenges certainly becomes clearer.

If you’re stumped with trying to get your head around all of the different solutions in the market, this is where we can help.

That’s what we do!

We help confused procurement leaders to narrow down which procurement tools match their unique requirements to solve their specific pain points.

What is the business case to fix dirty procurement data?

This brings us to the final piece of the puzzle. How can you convince your budget holder or economic buyer that this is a problem worth investing in to fix?

The fundamental case for doing this is that it’s not a COST. It’s an essential, long-term INVESTMENT. If you don’t do it, you’re putting yourself at a significant disadvantage. Amazon has trounced their competition partly as a result of them having world class data.

We’ve come up with 5 key areas where there is a saving to be achieved or a potential business risk to be mitigated through having clean procurement spend data and vendor master data.

1) Maintaining basic due diligence

- Clean procurement data will enable you to easily track things like supplier financial stability and supply chain risks.

- Ensure that necessary documents – e.g. insurance certificates and ESG compliance requirements – are kept in one single source of truth

- Reduce the likelihood that contact information becomes outdated.

2) Risk Management

- Reducing the potential for any brand damage coming from possible supplier scandals

3) Bottom Line Savings

- Eliminating the opportunity for fraud or overpayment to go undetected.

- Reduction in freight costs otherwise resulting from incorrect lead times or incoterms in a vendor master record

- Leveraging negotiation potential through being able to see all spend from vendors within the same parent organisation.

4) Working Capital Improvements

- Reduction in material inventory thanks to accurate lead times and incoterms being maintained

- Improvements to Days Payable Outstanding (DPO) through accurate payment terms and early payment discounts

5) Cost Avoidance

- Reducing interruptions or stoppages to production resulting from incorrect specifications, batch sizes, lead times or incoterms.