We’ve entered an AI era where 76% of work can be augmented or automated.

However, only 3% of companies apply automated execution and 7% autonomous end to end planning. 2% of managers apply best practice decision methods. Hardly a recipe for improving planning & decision making.

Imagine the opportunity if we closed this massive planning, decision & execution gap with a new planning paradigm.

Supported by new operating models (Organizational design, processes, roles & responsibilities, incentives, measurement framework, mindset & behaviours, technology enablers). Exploiting AI and other technologies to get the best out of human and machine strengths.

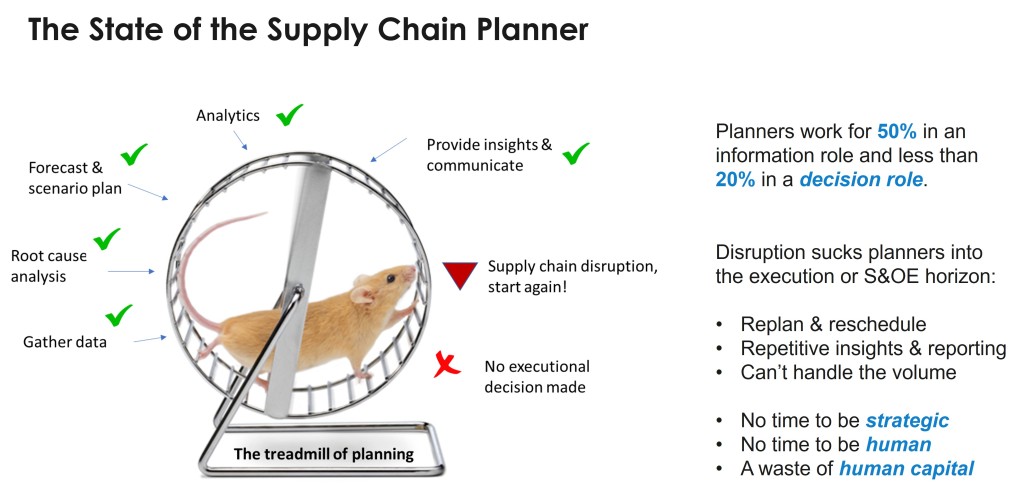

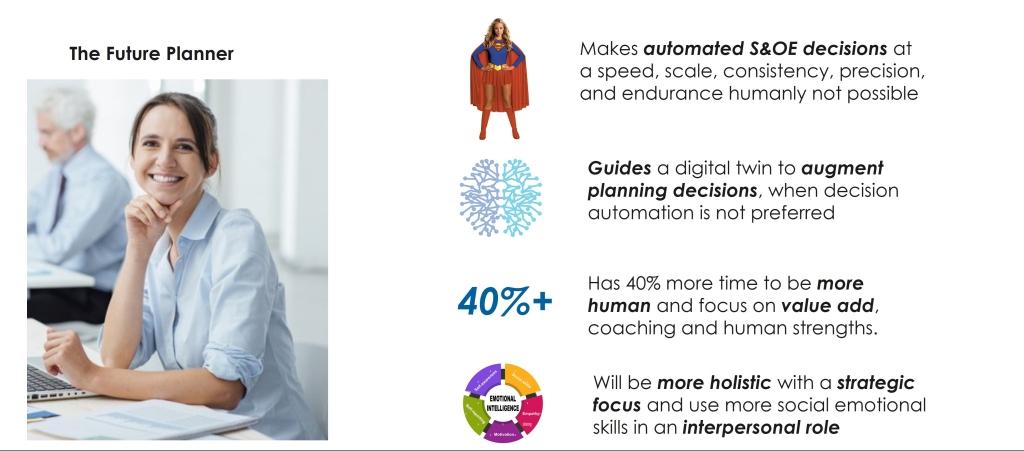

Imagine a planner with a more interesting and engaging job and career, supported by a machine that frees up 40% of their time to work on interesting stuff, rather than tinkering for 50% of their time with data and being on the treadmill of planning-disruptions-replan-replan-replan and make reports and IBP decks.

A planner of today versus a planner of the future

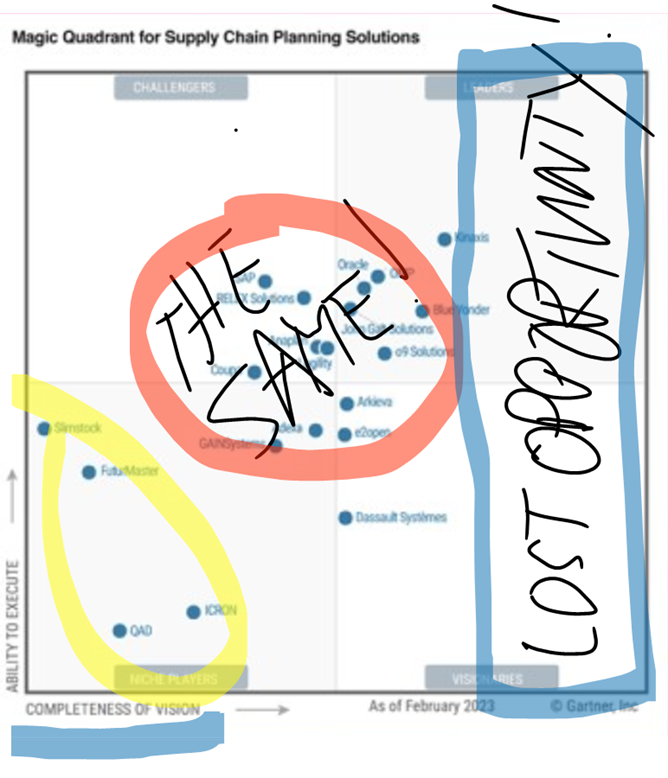

Unfortunately, the planning paradigm has hardly changed for the last 20+ years since I implemented SAP APO3.1 in 2001. The decision needle has not moved enough.

Now, two decades later, APS are in the maturity stage of their product lifecycle. This makes them a commodity in a crowded and competitive marketplace, just like the ERP systems that support them. If we look at the latest 2023 Gartner Magic quadrant for supply chain planning, we can make the following observations:

The same: In a mature market, APS vendors gravitate to the same vision & functionality.

Lost opportunity: Completeness of vision does not exceed 75% for any vendor, meaning lost opportunity.

Credits to Kinaxis for being the only one standing out a bit and leading in both vision and ability to execute.

However, in this age, a vision and new planning paradigm should describe a full planning symbiosis between human and machine and articulate what planning activities and decisions are made by the machine, what is augmented by the machine, and what remains human centric.

This is the lost opportunity currently not addressed by supply chain planning vendors and this void will need to be filled by new (Wave 3) technologies.

I’m looking forward to closing the gap, create new planning visions and a new planning paradigm!

Planners deserve it!

Niels, you hand written “lost opportunity” on the Gartner dot plot makes me think of all of the firms on the dot plot are just various flavors of “Coke” vs. “Pepsi”. Some are store brands or maybe some “Cherry Coke” or “Vanilla Coke” but all are the same.

It is actually spreadsheets with workflows that are the 90% and although not optimal do allow users to take their algorithms to the workflow not force people to come to a centralized algorithm.

The answer is in a hybrid of centralized and decentralized computing with workflows that link decentralized data to feed the plans and coordination of decentralized and distributed plans.

I know you are all about “cognitive computing” which I find to be a confusing term but the answer is in capabilities that create actual ROA, cashflow, reduction of workign capital

Dell did 60 inventory terms when I met with their committee in 1996 and helped them push out ERP vendors and use our Factory Planner then at i2. Today Dell does 14 inventory turns ? What is possible is Dell and its entire Ecosystem could be doing 100’s of inventory turns with the proper synchronization of data and plans ! This is a massive ROA, IRR, cashflow improvement. This should be the goal not glitzy shiny object BS IT terms !

Hi John,

Reading your comment I think we both agree that planners deserve a better vision am I right?

There are multiple angels to achieve that and both our thinking can play a role.

For me top of mind is not even ROA etc, but a planner that still pretty much does the same job as I did 20 years ago.

A waste of human capital!

PS. I like your Coke vs Pepsi analogy

Maybe that is the wrong goal ? It is not about the job it is about the goal, the intent, the objective. The objective is a highly productive supply chain / manfufacturing network not the job of planner. The tools to make this happend are involve dramitic improvement in the synchronization of assets and are enabld by a combinatio of people, process and technology.

I would strongly make the statement it is bringing the algorithms, the synced data, the insights held by planners to the broad workflows to everyone. Bring the planning data and process to the business workflow ! Don’t continue to require planners to override the workflow with some parallel inteligence. Additionally allow plans of all types, stripes, brands, flavors to interoperate ! Today every dot on the Gartner plot are just different flavors of Cola (Coke vs. Pepsi). There are not two of those products that can interact ? Think about it is like you installed Inkomi, Cisco, Juniper routers and bridges in a telecom network and there was not a fall back method to interoperate ? How effective would your Google serach or ChatGPT result be as would leave off 3/4’s of the search crawl ?

Obviously, there are many opportunities to both improve planner productivity but the REAL opportunity is to take the intelligence and democratize it into all roles, all locations, all nodes of the supply chain network. This is where the big huge jump in ROA, ROI, reduction of cycle time and strategically moving Western manufacturing as far away from bait and switch Communist China predatory buld to stock to more of build / configure to order adapt, adjust innovate Western manufacturing

Agreed John, if all could interact and democratize intelligence in all roles.

Also agree with your goals & opportunity, just saying that helping planners get a better job is meaningful to me.

Niels, supply chain success and in real business success it has to be “top down” but even more “bottom up” success. A goal without this realization rarely makes it out of the gate… as you well know !

So much of the ERP and big supply chain tech is built on a naive, cold accounting only, anti people prot IT message of force your people to work like a machine or eliminate the job mentality. Looses before it starts and is evident by the crap financial results of the all these tools past 20 years !

So finding methods to make planners enjoy their work be successful is powerful. I am amazed how so many companies put a very low level person in key planning jobs ?

To me every key supply chain planning job should be a team of a “Wharton style” finance guy teamed with an advanced system engineer / Industrial engineer to create the models and tune them to CEO / COO level goals, adjustments. All the best of an S&OP culture !

Every client we have worked with this is what they ended up with in the role but only after extensive work for the CEO to realize this view of S&OP WAS THE BUSINESS. Not some add on function of a half retired person in the basement ?

Anything, that can bring S&OP to the C level and use tools to synchronize to the forward look of the balance sheet, income statement, treasury to me is breakthrough ?